Engine Trolley: Difference between revisions

mNo edit summary |

mNo edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Workshop Equipment for Local Manufacture]] | [[Category:Workshop Equipment for Local Manufacture]] | ||

[[File:Vw600.1-1.png|thumb|alt=Cover page for VW 600/1 Engine Trolley|Cover page for VW 600/1 Engine Trolley]] | [[File:Vw600.1-1.png|thumb|alt=Cover page for VW 600/1 Engine Trolley|Cover page for VW 600/1 Engine Trolley]] | ||

[[File:Vw600.1-2.png|thumb|alt=Instruction page for VW 600/1 Engine Trolley|Instruction page for VW 600/1 Engine Trolley]] | |||

[[File:Vw600.1-3.png|thumb|alt=Blueprint for tool VW 600/1 Engine Trolley|Blueprint for tool VW 600/1 Engine Trolley]] | [[File:Vw600.1-3.png|thumb|alt=Blueprint for tool VW 600/1 Engine Trolley|Blueprint for tool VW 600/1 Engine Trolley]] | ||

The engine trolley provides a safe support for the engine with the car or a hoist, or supported by a gantry crane. It also enables the engine to be moved about easily. The trolley runs on two non-swivelling wheels and two castors and is therefore highly manoeuvrable, whilst the welded-on cradle pads match the shape of the crankcase and thus entirely eliminate any possibility of damaging the engine when lowering on to the trolley. | The engine trolley provides a safe support for the engine with the car or a hoist, or supported by a gantry crane. It also enables the engine to be moved about easily. The trolley runs on two non-swivelling wheels and two castors and is therefore highly manoeuvrable, whilst the welded-on cradle pads match the shape of the crankcase and thus entirely eliminate any possibility of damaging the engine when lowering on to the trolley. | ||

Other examples of uses to which the engine trolley can be put are given in "Local Manufacture of Workshop Equipment" under Nos. VW 605, VW 606 and VW 633 as well as in the VW Workshop Manual. | Other examples of uses to which the engine trolley can be put are given in [[:Category:Workshop Equipment for Local Manufacture|"Local Manufacture of Workshop Equipment"]] under Nos. [[VW 605]], [[VW 606]] and [[VW 633]] as well as in the VW Workshop Manual. | ||

=== Construction Details for VW 600/1 === | === Construction Details for VW 600/1 === | ||

| Line 13: | Line 14: | ||

# Bend tube (7) as shown on drawing. | # Bend tube (7) as shown on drawing. | ||

# Weld up tubular components (5), (6) and (7) and round bar (8) as shown on drawing. | # Weld up tubular components (5), (6) and (7) and round bar (8) as shown on drawing. | ||

# Weld longitudinaly halved tubes 10 | # Weld longitudinaly halved tubes (10) and square bars (9) to round bar members (8) adjacent to the flats, as shown on the drawing. | ||

# Mark off positions of tapped holes for castors and non-swivelling wheels (| and (2) on mounting pads (3); drill four 6.5 mm (0.256 in.) holes in each pad and countersink. | # Mark off positions of tapped holes for castors and non-swivelling wheels (|) and (2) on mounting pads (3); drill four 6.5 mm (0.256 in.) holes in each pad and countersink. | ||

# Weld mounting pads (3) to tube ends (5). | # Weld mounting pads (3) to tube ends (5). | ||

# Screw castors and wheels to pads, using countersunk screws (4). | # Screw castors and wheels to pads, using countersunk screws (4). | ||

# Paint trolley. | # Paint trolley. | ||

# Grease all bearings. | # Grease all bearings. | ||

Latest revision as of 19:57, 18 November 2023

The engine trolley provides a safe support for the engine with the car or a hoist, or supported by a gantry crane. It also enables the engine to be moved about easily. The trolley runs on two non-swivelling wheels and two castors and is therefore highly manoeuvrable, whilst the welded-on cradle pads match the shape of the crankcase and thus entirely eliminate any possibility of damaging the engine when lowering on to the trolley.

Other examples of uses to which the engine trolley can be put are given in "Local Manufacture of Workshop Equipment" under Nos. VW 605, VW 606 and VW 633 as well as in the VW Workshop Manual.

Construction Details for VW 600/1

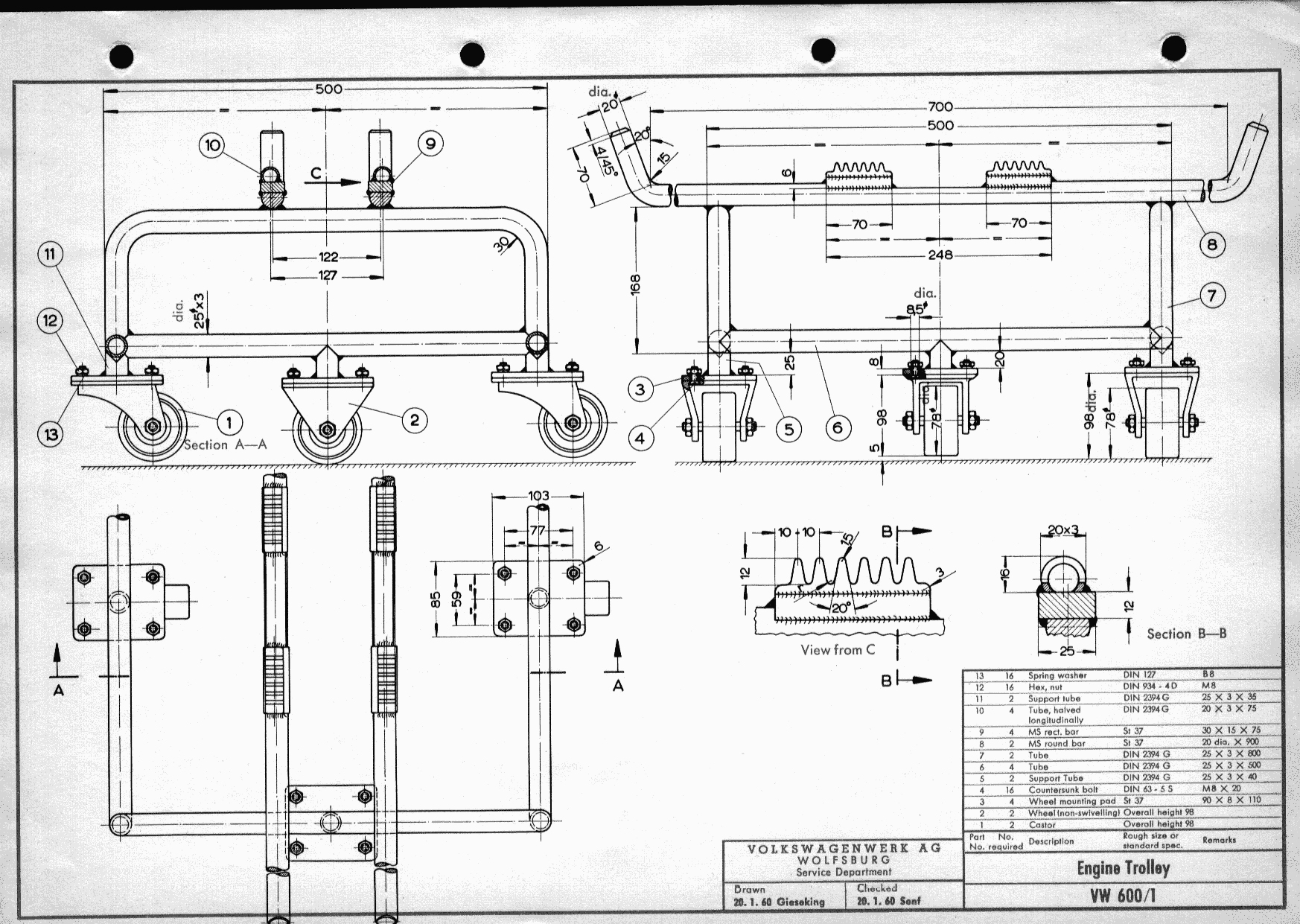

- Cut oll tubes, strip and round bar to dimensions given in lis of parts.

- Bend round bar (8) as shown on drawing, cut off accurately to length and work the flats as indicated (depth 6 mm = 15⁄64 in.].

- Bend tube (7) as shown on drawing.

- Weld up tubular components (5), (6) and (7) and round bar (8) as shown on drawing.

- Weld longitudinaly halved tubes (10) and square bars (9) to round bar members (8) adjacent to the flats, as shown on the drawing.

- Mark off positions of tapped holes for castors and non-swivelling wheels (|) and (2) on mounting pads (3); drill four 6.5 mm (0.256 in.) holes in each pad and countersink.

- Weld mounting pads (3) to tube ends (5).

- Screw castors and wheels to pads, using countersunk screws (4).

- Paint trolley.

- Grease all bearings.